Welcome to Scrappy Brothers! We're a small, local operation based in Holiday Island, focused on supporting our community with leatherworking creative projects.

We’re hands-on creators, offering:

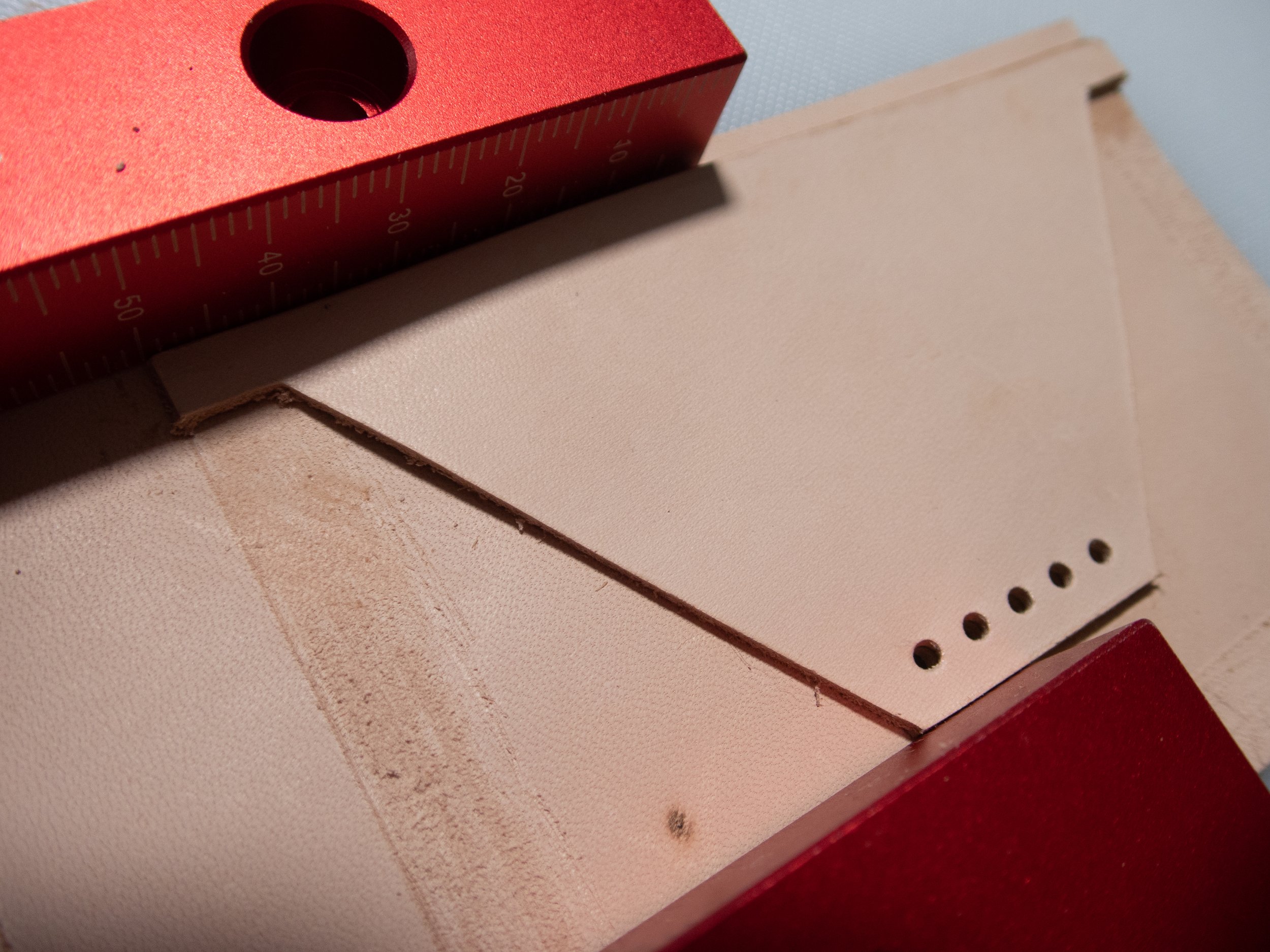

Leatherworking.

Soon UV Printing.

Soon 3D Printing

Soon Laser Etching/Cutting

We focus on small custom jobs and personalized pieces, perfect for gifts, hobbyists, or unique branding.

We're not a big shop—just passionate problem-solvers who care about doing great work for our neighbors.

Thanks for stopping by, we look forward to making something you’re going to enjoy!

Little over enthusiastic I guess. I probably need to lay off the caffeine.

Email stuff :: I’ll collect Emails but only to reply to customers or notify them of any changes to a job.